Leading the way into the future of geomembrane innovation.

By Leah Kellar

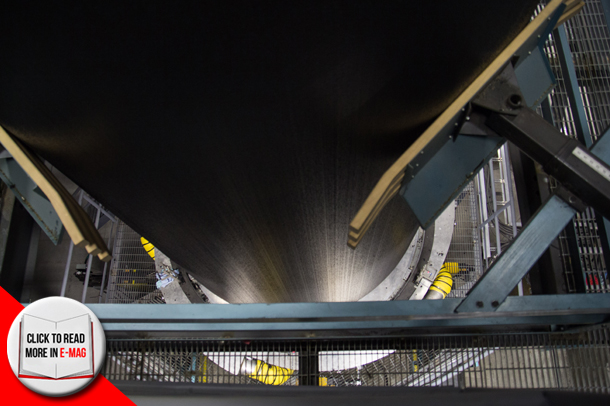

As the third largest geomembrane manufacturer in the world, Solmax International Inc. has literally covered the world and protected the earth for more than 30 years as a leader in an increasingly competitive commodity niche market. Geomembranes are used in a myriad of environmental, geotechnical, hydraulic, transportation and private development applications everyday, such as: protective liners for municipal and hazardous waste landfills cells and covers, tailings and heap leach pads for mining operations, irrigation and water reservoirs and canals, secondary containments for oil and gas extractive sector—just to name a few. Geomembranes often act as the last defense separating or containing elements from one another, which if brought together could cause serious health or safety problems among others.

This makes the raison d’être of Solmax, an international company with its headquarters in Varennes, Quebec, a vital one. The manufacturing of HDPE and LLDPE geomembranes, and fluid transportation services to the mining industry are the company’s two core services through which it offers synthetic products destined for separation and/or confinement solution of solids and liquids and water treatment in the construction, engineering and environment sectors. For example, geomembrane and fluid transport products that allow the separation or confinement of harzardous waste liquid from seeping into the potable or reserve water supply. It’s a vital niche market that improves the quality of life and societal wellbeing each day, of which the public knows very little about on average.

But the public doesn’t have to know to reap the daily benefits of its innovation. Solmax has collaborated with the biggest names in the mining, petroleum, waste management, water and civil engineering sectors, and its products are sold in over 60 countries. With more than 30 years of experience, contacting Solmax means having access to technical information based on hundreds of already implemented projects. Some of these projects have involved innovative applications for aquaculture, energy, landscaping, mining, waste and water. Solmax geomembranes have been extensively used in fish and shrimp pond projects in South-East Asia and Central America as they prevent both waste accumulation in the soil and leaching of harmful chemicals into the ponds such as ammonia and hydrogen sulphide. Solmax geomembranes have been used in some of the largest energy projects in the world including coal ash or Coal Combustion Residual (CCR) containment projects as they offer the safest and most economical CCR handling and storage method, lining of coal beds and coal seam basins to avoid safety risks, lining of fracking chemical tanks, well pads, ponds for freshwater storage and flow-back water, thus protecting the environment during the extraction process.

In the mining sector, Solmax membranes are used in a variety of applications from heap leach pads, evaporation ponds, brine ponds and tailing dams around the world.

Some of the most remarkable projects that Solmax is known for in the industry go back to the company’s beginnings approximately three decades ago involving some of the largest waste projects in the world—whether for municipal solid waste landfills, hazardous waste landfills, wastewater treatment and bioremediation projects—Solmax membranes are an integral part of waste management containment systems across the globe. In tandem with this, Solmax membranes are used in various clean water applications including water ponds, irrigation and navigation channels, potable water reservoirs, floating covers and wastewater treatment facilities.

Solmax today looks back on these achievements and finds itself a leader, but in a different competitive climate. At the time of its start in 1981, Solmax was one of only a few in the industry, now things have changed so much that general manager, Jean-Louis Vangeluwe, says the company’s biggest challenge is to develop new products for new applications and to grow and diversify from the international standard. The geo-membrane business is now an international business and Solmax is an international company with a manufacturing plant in Quebec that very efficiently covers the areas of America, Europe, Western Russia and the Atlantic coast of Africa. Another plant in Malaysia strategically covers Asia, India, Australia, the Middle East and Eastern Russia. Solmax piping division is located in proximity of Chilean mining companies.

Listed as one of Canada’s Best Managed Companies in 2012, this recognition for effective management was not earned overnight. Solmax started strictly in the distribution business, then began an overhaul into installation because they recognized an unmet need in the market for it, then ventured into the manufacturing side of the industry in 1997. That’s when Vangeluwe started set to work on the process of selling globally which required new IT, HR, manufacturing and quality control processes. The company founder, Jacques Côté, helped by the CEO Marc André Gervais, was looking for someone to develop the business internationally through a set of sales networks, while he would continue to concentrate on development of the company in Quebec. Vangeluwe, a commerce and MBA graduate with extensive travel and work experience in several countries such as South East Asia, Australia, Chile, and Spain proved to be just the right man for the job.

“We actually build all of the processes and all of the assistance to be able to operate with a very low number of people,” recalls Vangeluwe, whose objective is to strengthen the company’s profitability and growth. “We’re quite proud of the award for Best Managed Companies in 2012, it is the result of all of the energy and force we put into building a lean, mean, energy-efficient company to be able to export so many years ago.”

This meant changing and developing HR policies in order to retain people and motivate them to transition from a small company to one that could serve an international market.

“We actually built a company in Asia, so we adapted to the Asian culture and managed it from a distance. It’s one thing to be located in Quebec with all of your people here, but when you start to have a company in Chile and a company in Asia while being as efficient as you are in Canada, then you need to go through a huge amount of different issues to be addressed in all sectors of the business,” said Vangeluwe.

Solmax has been the recipient of numerous provincial exporting awards over the years, in part because there is not very many medium-sized companies in Quebec that are exporting to more than 60 companies efficiently. While it is not a big company like Bombardier for example, Solmax does have a very similar internal operational process because is serving an international market.

Now, as Vangeluwe stresses, the challenge for the company is to find new sectors that the geomembrane can be used in for different applications. He notes that at the beginning in the 80’s and ‘90s it was a complicated process for plastic manufacturing companies to make the product, but now with history, experience and the mining boom of 2010-2011, there are more people getting into the game.

“Now we have a larger ratio between demand and supply, so that is not very comfortable,” he said.

Finding skilled labour, a traditional challenge for many companies in this economy, is not one for Solmax however, due to the fact that manufacture of geomembranes is highly automated. Looking ahead, Vangeluwe identifies the short-term five to ten year goal for Solmax as being close to where the energy will be very cheap.

“The United States is looking to be the place for that, because what is happening now is that people are coming back to North America because the energy there is going down thanks to natural gas. So it’s going to be much more convenient to be in North America than to settle manufacturing plants to other countries,” said Vangeluwe noting Western Canada and the Northeastern part of the United States as places Solmax has its sights set on.

Solmax would not be where it is today without the help of its many partners who were there from the very beginning transition in 1997 and without the energetic action of CEO Marc André Gervais who run the business till 2012.

“Our Partners actually took part of the financial risk when we decided to develop this business internationally,” said Vangeluwe. It is an investment-driven business that requires money on the table before going into mass commercialization of the product.

In the light of the current recession in the mining industry, Vangeluwe admits that after 30 years pioneering the way, gaining first position in international geomembrane manufacturing will be a matter of finding the right opportunities, and the right place to develop and sell its products, but in the process Solmax International Inc. will continue to lead the way as it has from the very beginning.