By Anna Guy

Founded in 1973, SBB is a world leader in the design and manufacturing of Emergency Restoration Systems (ERS), wind measurement towers and other structures made of aluminum extrusions. Proudly located in Blainville, Quebec, SBB is rooted in steel and aluminium manufacturing, having turned its focus to aluminum—and the manufacturing and design efficiencies it affords the transportation sector, specifically—in 2015.

“Everyone is looking for gains in terms of weight—its all about efficiency, the lighter you get the more efficient you become,” says SBB General Manager, Patrick Gharzani. “That’s the track we are on right now.”

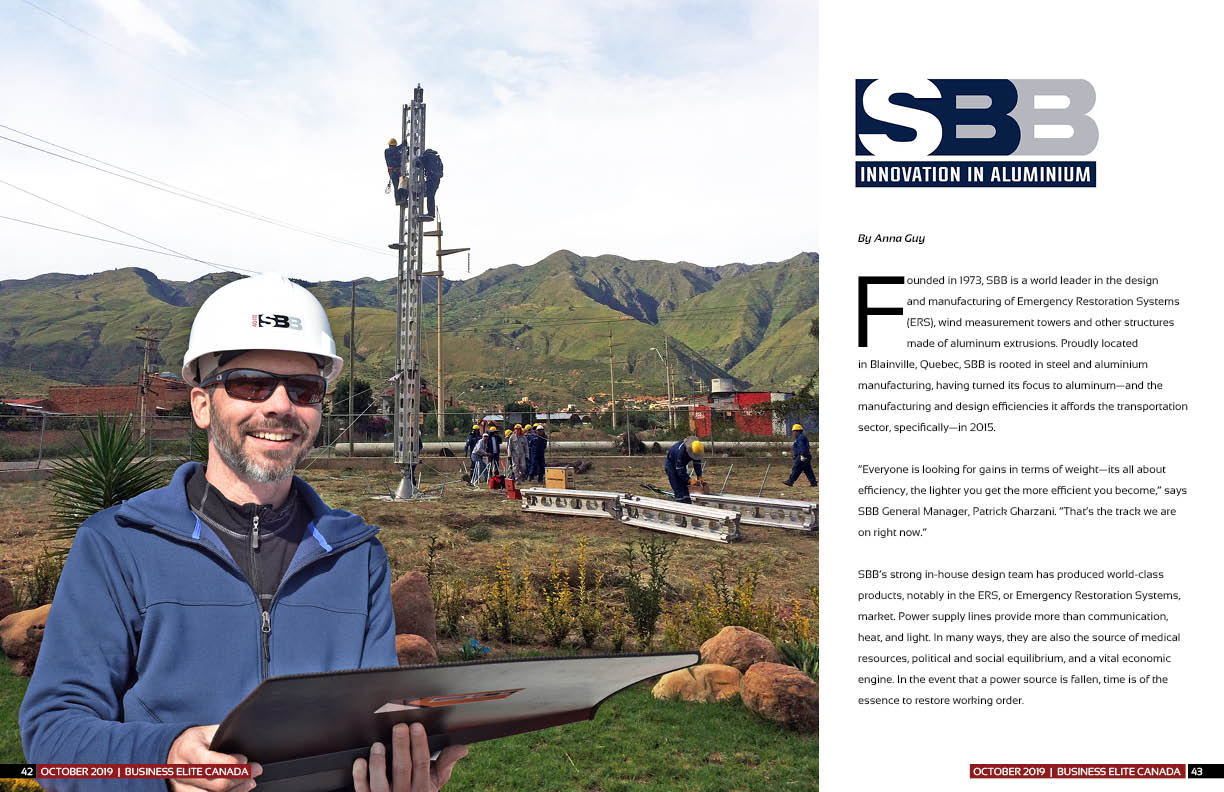

SBB’s strong in-house design team has produced world-class products, notably in the ERS, or Emergency Restoration Systems, market. Power supply lines provide more than communication, heat, and light. In many ways, they are also the source of medical resources, political and social equilibrium, and a vital economic engine. In the event that a power source is fallen, time is of the essence to restore working order.

SBB’s ERS towers are modular aluminum guyed structures. By establishing a temporary bypass of damaged towers, they can help quickly restore power on a power transmission line from 69kV to 1200kV. Designed for ease and speed of installation, the ERS can be installed on all types of ground in any weather.

“They are designed to work like Lego blocks,” explains Gharzani, “without the need for heavy equipment to put them together. The intent is to restore damaged power transmission lines, for example in the event a tower is wiped out by a hurricane, so you can restore power on that line in the matter of a few hours.”

The company is certified ISO9001:2015 and complies to a long list of internationally recognized standards. All its products are exhaustively tested in a dedicated R&D area in the SBB factory, often in presence of clients. Once client approval is given, the ERS are loaded into containers that are shipped to all corners of the world. Upon reaching its final destination, the ERS towers are ready for action and will ensure safety and protection of power grids in over 57 countries and counting, a testament to the strong network of local representatives throughout the world.

“Our first customer was a Mexican company,” says Gharzani. “A customer of ours recommended us, and we were able to produce something very effective for them. From there, we thought if they need this, other companies in the same field will as well. And the result was several generations of what is today the leader on the market, our emergency tower.”

From Mexico, Gharzani says the next natural step was to expand ERS’s into the North American market, then South America, and to slowly expand to Europe and Asia, with everything being made in Quebec. “You need to hire the right people and have the right attitude when it comes to export” says Gharzani. “It takes a lot of investment before you get a return, so you need to be patient and cautious to make sure you don’t lose money, because a wrong decision could cost hundreds of thousands of dollars.”

SBB enjoys both a worldwide clientele while remaining proudly Canadian. “We are very proud to fly the Canadian flag, so to speak, and it definitely helps us,” says Gharzani. The company can also count on a stable and dedicated workforce of passionate people with multicultural backgrounds. SBB’s efforts to offer a work-life balance to its employees was recently recognized by the Ministry of Family and the Quebec Young Chambers of Commerce, that have awarded the company a prize for its work-life initiatives.

Gharzani says that since the ERS services are so successful, SBB is looking to diversify its services. With diversification as the next step, manufacturing for the transportation sector presents a strong and exciting opportunity for the company. SBB is a subcontractor for a major global multinational rail equipment manufacturing company, having manufactured roofs for train cars since 2014, and looking to expand in this area.

“We want to continue to develop this kind of activity, manufacturing industrial structures different from the towers, and more of a local active geared towards business manufacturing companies,” says Gharzani. Look out for the SBB sign in maritime manufacturing areas and shipyards in the future, as this is also in their sights.

Whatever they choose, the SBB expertise in engineering, aluminum welding as well as the its flexible production system will help them to take on whatever challenge their clients come up with. Says Gharzani, “While we continue to grow on a steady path in our core service, we are putting a lot of effort into other paths where we feel we will experience some interesting growth.”

www.sbb.ca