Nuclear Power Station Hitting Refurbishment Goals

By Tina Costanza

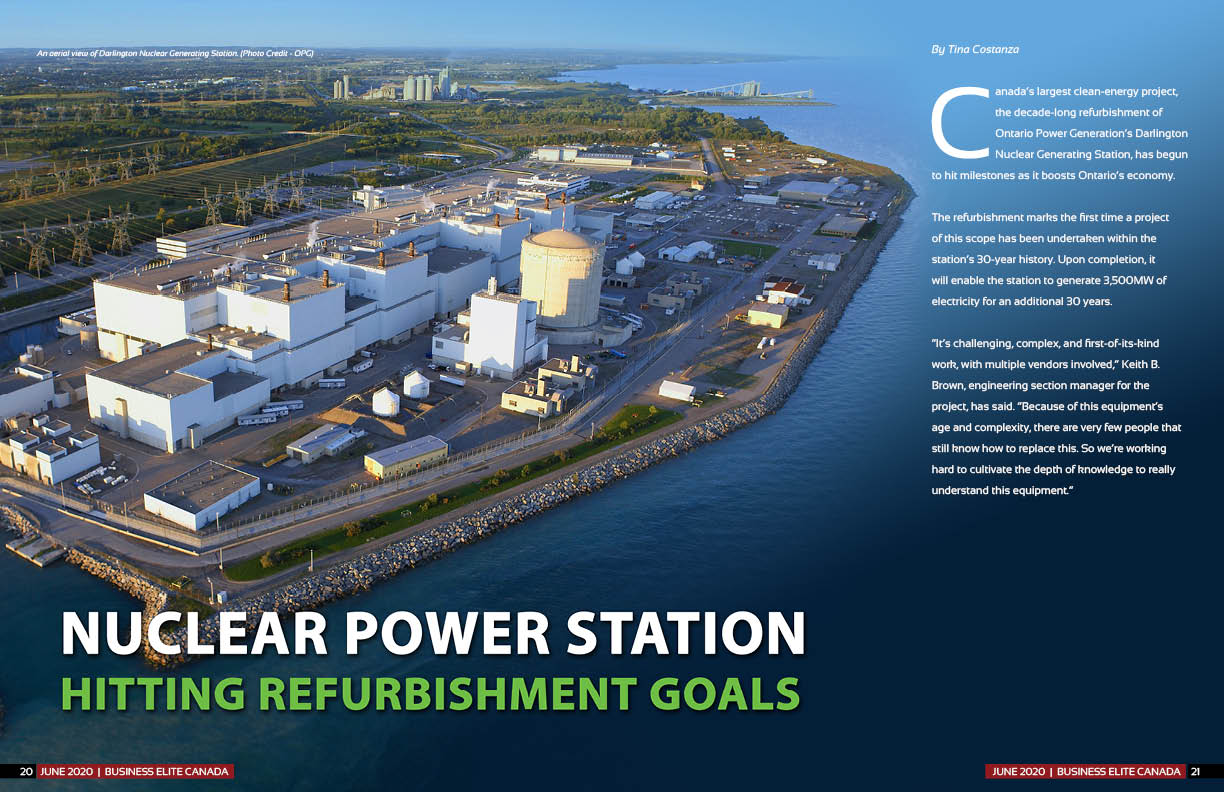

Canada’s largest clean-energy project, the decade-long refurbishment of Ontario Power Generation’s Darlington Nuclear Generating Station, has begun to hit milestones as it boosts Ontario’s economy.

The refurbishment marks the first time a project of this scope has been undertaken within the station’s 30-year history. Upon completion, it will enable the station to generate 3,500MW of electricity for an additional 30 years.

“It’s challenging, complex, and first-of-its-kind work, with multiple vendors involved,” Keith B. Brown, engineering section manager for the project, has said. “Because of this equipment’s age and complexity, there are very few people that still know how to replace this. So we’re working hard to cultivate the depth of knowledge to really understand this equipment.”

The refurbishment involves replacing critical components of the CANDU reactors. Work began in October 2016, starting with the second of four units.

The Unit 2 reactor achieved first criticality on April 9 this year. That means the reactor has initially shown its capacity to maintain a sustained chain reaction and create the energy needed to produce electricity, said Jeff Richardson, senior vice-president, Nuclear Projects.

Dietmar Reiner, chief project officer, described the milestone as a historic moment, when “essential services like ours are needed more than ever.”

The $12.8-billion refurbishment, and its subsequent three decades of station operation, are expected to generate $89.9 billion in economic benefits for Ontario, create 14,200 jobs per year, and increase personal income by an average of $1.6 billion on an annual basis, according to an independent report by the Conference Board of Canada.

With 96 per cent of project costs spent in Ontario and the hiring of Ontario-based contractors, for every $1 spent on the project, Ontario’s GDP is expected to rise by an average of $1.40.

In addition to bolstering Ontario’s economy, an independent report prepared by Intrinsik Environmental Sciences suggests the operation of the station from 2024 to 2055 will prevent greenhouse-gas emissions equivalent to roughly 297 megatonnes of carbon dioxide or the removal of 2 million cars off Ontario’s roads per year.

Darlington Nuclear Generating Station lies 70 kilometres east of Toronto in Clarington, Ontario. It consists of the four units that generate more than 20 per cent of Ontario’s electricity needs, or about 31 million megawatt hours of electricity annually — enough to power 2 million homes.

Ontario Hydro built the facility between 1981 and 1993, with Unit 2 being the first to be brought online in 1990. Unit 1 followed in 1992, and Units 3 and 4 were brought online in 1993. In April 1999, Ontario Hydro was split into five component Crown corporations with Ontario Power Generation (OPG) taking over all electrical generating stations.

Responsibility for long-term plans to establish an appropriate mix of electricity supply in the province, however, falls to the government of Ontario. The province has determined that a mix of options is the best approach for ensuring a safe, secure and reasonably priced electricity supply for its residents.

OPG announced in February 2010 that its plans for the refurbishment would go ahead, and it established financing for the project as part of its work program. OPG’s general operations have funded the initiation and execution preparation phases of the project.

Contracts for the refurbishment indicate the project will provide apprenticeship opportunities for skilled trades workers, including welders, electricians, carpenters, insulators, ironworkers, boilmakers, crane operators, heavy equipment mechanics and operators, construction millwrights and industrial mechanics, and steam, pipe and gas fitters. OPG’s aim is to have apprenticeships make up 20 per cent of the workforce on the project.

While workers carry out their duties, the station will continue to operate. Each unit will be taken offline, one at a time, to be safely rebuilt.

In Canada, nuclear power plants are subject to oversight and regular licence renewal by the Canadian Nuclear Safety Commission (CNSC). OPG is filing reports to the CNSC at various stages throughout the project. These reports are subject to approval by the commission.

The CNSC has already agreed there would be no significant adverse environmental effects, given available mitigation actions, as a result of the refurbishment and continued operation of the reactors.

Darlington’s Integrated Safety Review confirmed the plant met modern codes and standards, and that it has been using industry best practices.

A Global Assessment Report, which is an overall risk judgment on the acceptability of continued plant operations, deemed the plant safe and reliable.

Two independent oversight organizations have also been established for the project. One reports to the project executive and the OPG board of directors, and the other reports to the Ontario Ministry of Energy, Northern Development and Mines.

The team behind the refurbishment is comprised of OPG’s partners, industry experts, energy professionals, and tradespeople. Participating organizations include power generation technology builder GE Power; builder and fabricator ES Fox Construction; contractor Black & McDonald; fuel and fuel bundle provider BWTX Canada; and CanAtom Power Group, which is focused on the refurbishment’s retube and feeder replacement program.

During the refurbishment, each reactor will be taken out of service for about three years so the team can replace fuel channels, feeder pipes, calandria tubes and end fittings; rehabilitate steam generators, turbine generators and fuel handling equipment; improve systems; and complete plant upgrades to meet regulatory requirements.

About 480 pressure tubes and calandria tubes, and 960 feeder pipes for each reactor will be removed and replaced as part of the project.

But first, before disassembling a reactor, workers must disconnect it from the power grid. This requires removing fuel and heavy water, and isolating the unit from the rest of the station in a process known as islanding.

The next step is disassembling the reactor, which includes removing, storing or replacing thousands of components with specialized tools that workers operate by remote control. Reassembling the unit requires just as much precision to inspect, clean and install the components.

The last step is powering up the unit by following several step-by-step approvals. These confirm the quality of the work and ensure that staff, equipment systems and operating procedures are ready for the start-up process. Workers, meanwhile, refill the moderator with heavy water, load fuel into the fuel assemblies in the reactor core, and fill and pressurize the heat transport system.

Then the nuclear fission process is started and the unit begins to warm up. Workers restore containment and then begin reconnecting the unit to the rest of the operating station. The goal now is for the unit to achieve criticality, OPG explained.

After final high power testing, control room operators gradually raise the unit to full-power operation.

The project has remained on budget and on schedule, OPG has reported, despite the COVID-19 pandemic.

Refurbishment of Unit 1 has been scheduled to start in the second quarter of 2022, and is expected to be finished in the second quarter of 2025. Refurbishment of Unit 4 is to begin in the fourth quarter of 2023, with completion set for the fourth quarter of 2026.

The refurbishment of Unit 2 was ahead of schedule to meet the revised completion date in May. More than 99 per cent of Unit 2 work has been completed as of mid-May, and 58 of 58 systems have been returned to service. OPG declared construction complete on Unit 2 in March, following the successful restoration of the airlocks and vault containment pressure tests.

Prior to the pandemic, the team was on track to begin Unit 3’s refurbishment in April. OPG has now decided to keep Unit 3 running to ensure a stable supply of clean electricity for Ontario, and to defer the start of its refurbishment to the third quarter of 2020.

Along the way, OPG has been doing its part to control the spread of COVID-19 at the plant by implementing increased health and safety measures across its sites. These measures include reducing the number of workers on site, facilitating physical distancing, and monitoring the health of staff. These efforts, combined with nearly 10 years of planning and preparation, helped ensure workers were able to complete Unit 2 construction safely and up to standard.

Subject to the state of the pandemic, OPG is preparing to resume prerequisite field work in June on the Unit 3 project and to facilitate the safe start of its refurbishment in the fall.

“This will allow us to maintain our focus on the safe completion of Unit 2, monitor the status of the pandemic and its impact on the project, and to ensure steady access to the resources required for the upcoming phases of work,” said Richardson. “We’re looking at this extended timeline as an opportunity. As we prepare for Unit 3 refurbishment, we’re working closely with our project partners, vendors, suppliers and unions to ensure we hit the ground running when the time comes.”

Bill Owens, senior vice-president of Unit 3 refurbishment, said that given the uncertainty surrounding COVID-19, it’s safe to say the pandemic will determine the timeline.

“We’re monitoring the situation and are planning accordingly,” Owens said. “Based on what we know right now, we stand ready to start the refurbishment of Unit 3 this fall.”

*Source www.opg.com

www.opg.com/strengthening-the-economy/our-projects/darlington-refurbishment/

www.opg.com/strengthening-the-economy/our-projects/darlington-refurbishment/whats-involved/

www.opg.com/strengthening-the-economy/our-projects/darlington-refurbishment/project-team/

www.opg.com/strengthening-the-economy/our-projects/darlington-refurbishment/refurbishment-faqs/