It’s a great sign when your company’s 20th year is its strongest yet. Such is the case for Steelcon, the Brampton, Ontario based structural steel firm.

What started in 2002 as a two-man team has expanded to 200 employees who work on some of Canada’s biggest infrastructure projects from commercial to industrial, healthcare, transit, public and government and more.

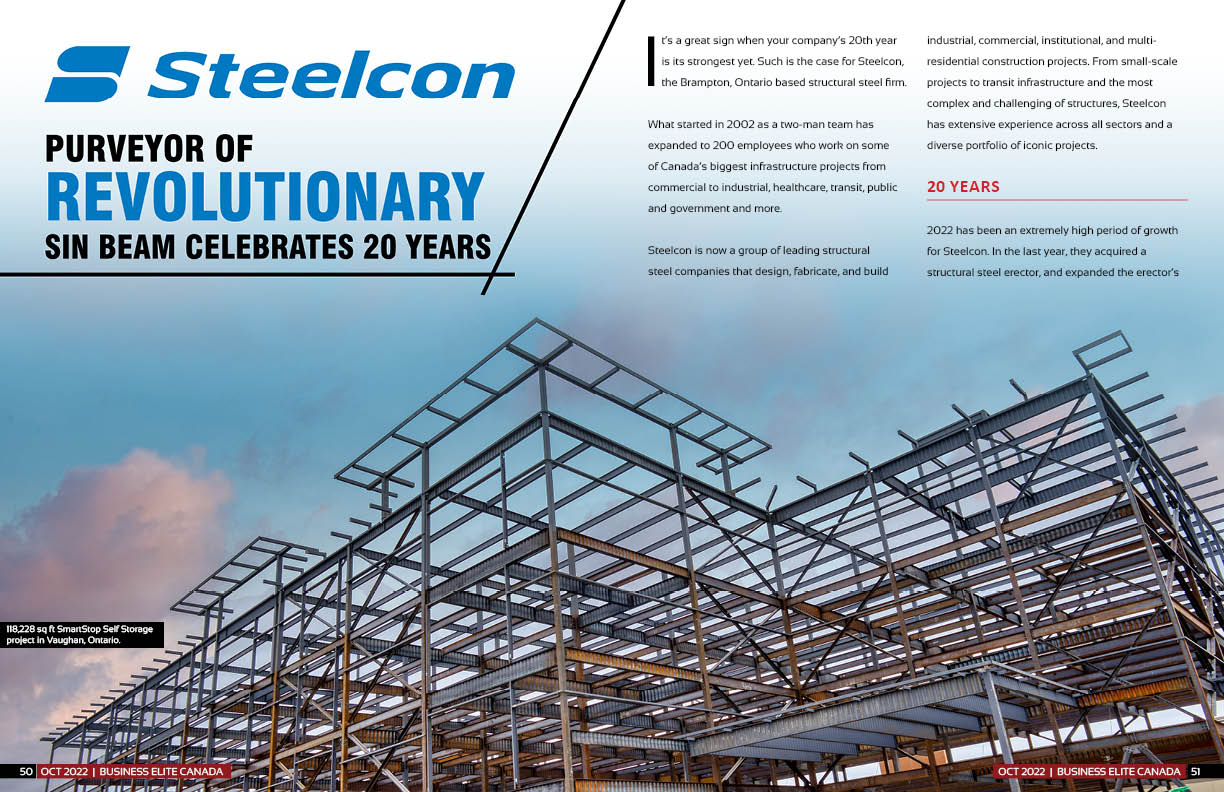

Steelcon is now a group of leading structural steel companies that design, fabricate, and build industrial, commercial, institutional, and multi-residential construction projects. From small-scale projects to transit infrastructure and the most complex and challenging of structures, Steelcon has extensive experience across all sectors and a diverse portfolio of iconic projects.

20 Years

2022 has been an extremely high period of growth for Steelcon. In the last year, they acquired a structural steel erector, and expanded the erector’s capabilities further with the launch of a dedicated deck installation division. This acquisition came on the heals of establishing joist fabrication capabilities at one of the Steelcon production facilities in St. Catharines. These initiatives are aligned with the firm’s vertical integration strategy and further strengthen Steelcon’s expertise while delivering new levels of value for its clients.

“In a busy market where schedules are changing, this cradle to grave strategy gives us a level of certainty and control of the process that allows Steelcon to continue providing exceptional service to clients while ensuring that the highest quality product is delivered on schedule,” says Danny Bianco, President.

“Working to build a level of trust that evolves into a strong working partnership, whether that was clients, suppliers, or employees, was a priority in the early Steelcon days, and despite our continued growth, we have remained true to those roots—and always will,” says Bianco.

“Our vision was to conduct our business with respect for candidness, truthfulness, and high standards of integrity. We have always prioritized meeting expedited schedules and ensuring that the highest-quality product is always delivered on time.”

SIN Beam

Ontario residents have benefited from Steelcon’s many notable projects, whether they are aware of it or not. Many GO Stations, malls, civic and commercial office buildings, and hospitals around Ontario boast the Steelcon stamp of approval. “When you pass a Steelcon project, whether it’s under construction or completed, there is a sense of pride,” says Bianco. “We take pride in our work and in the quality of our work. From warehouses to office buildings to hospitals and healthcare facilities, we’re building the strong and stable structures that serve our community, and we deliver on time, on schedule, on budget, and we do it safely.”

Many of these projects were completed successfully using the revolutionary SIN beam, the only structural steel product of its kind in North America. In 2015, Steelcon introduced the SIN Beam product to the Canadian market, which uses an innovative design that is up to 30 per cent lighter than conventional Wide Flange beams, and has been making big waves from coast to coast.

Steelcon’s proprietary SIN beam is a wide flange steel member composed of two flanges welded to a corrugated web. This sinusoidal profile makes it more efficient than a conventional rolled beam. The span to weight ratio matches—and can even top—that of open web girders while providing the stability and flexibility of a wide flange beam.

In addition to providing flexibility for longer spans, SIN beam members can also be used as girders or purlins in floor or roof construction, as columns or rafters in single or multi-bay frames, and anywhere a wide flange steel beam, truss, or joist girder may be used. SIN beam’s unique appearance can also make it an ideal element of architectural design.

Corrugated web steel beams have been an integral product in steel building construction in Europe and other parts of the world for more than 30 years. “Today, SIN beam is available in North America, exclusively through Steelcon, and to date we have more than 14.5 million square feet of SIN beam projects in our portfolio,” says Bianco.

Looking Forward

Steelcon focus is currently on an expansion plan that will bring SIN beam to the US market. With a well-established record of success with SIN Beam projects in Canada, Steelcon intends to build on this foundation in the US.

The development of a composite floor panel system that takes advantage of SIN Beam’s sinusoidal profile to provide a cost-effective solution for mid/high rise projects is also on the top of the list for the team’s R&D department.

And of course, sustainability is always top of mind, says Bianco. “We are fully engaged in energy modelling with the goal of creating green production facilities with reduced energy consumption and sustainable operations,” says Bianco. “We know the transition to net zero is a shared responsibility, so we are constantly questioning how we can advance and accelerate the transition in not just the steel/building materials industry, but the construction industry as a whole.”

To that end, our Research and Development department is also working on a project to determine the reduced carbon impact of a SIN Beam designed structure vs a conventionally designed structure and investigating further decarbonization strategies and opportunities to lower the emissions of a SIN Beam designed structure to make it truly carbon neutral. The next step would be to embark on an initiative to educate owners, designers and general contractors about the ability to achieve early and significant carbon reduction through the use of SIN Beam design.

For more information, please visit www.steelcon.ca