By Anna Guy

When it comes to the most environmentally sensitive and complex pipeline projects in the country, companies like Enbridge and TransCanada turn to Innovative Pipeline Crossings (IPC).

For instance, as a part of the 2015 Enbridge GTA project, a nearly $1 billion, large diameter gas pipeline being constructed in the greater Toronto area, IPC successfully completed the tunneling portion of the project—a 458-meter long pipeline was installed, crossing under both the Credit River as well as a set of railway tracks (not a straight-forward job when you take the weather, geology and unfavourable drilling conditions into account). Or the TransCanada Grande Prairie Mainline Loop project, the first National Energy Board sanctioned Direct Pipe Installation in Canada, for which IPC installed 217 metres of continuously welded steel pipe for the Highway #16 crossing.

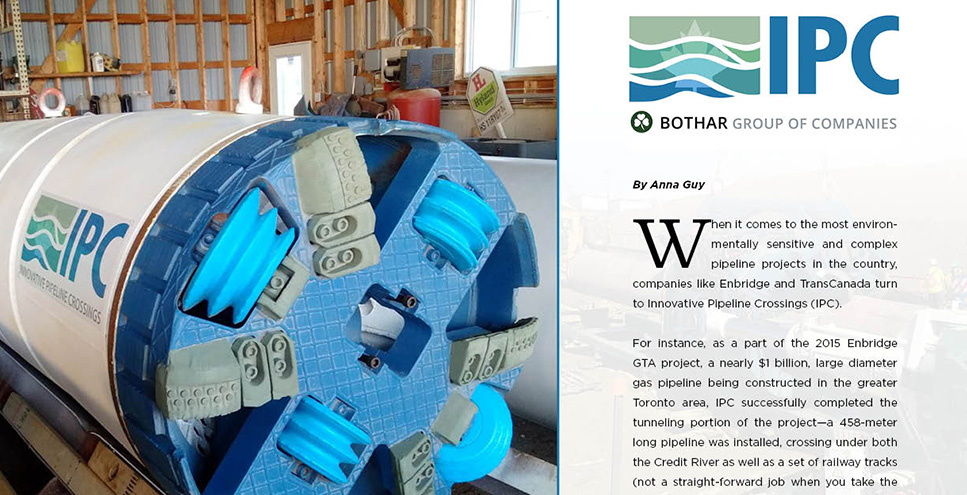

These projects, and others like them, received significant attention and interest from clients within the pipeline industry because of the Calgary based company’s Direct Pipe® technology, a German method that allows for the simultaneous excavation of the borehole and pipe installation—in other words, the project is done faster, easier, and with a smaller geographical and environmental footprint.

Direct Pipe® can be applied to nearly any ground condition with its one-pass pipeline installation method, making it an ideal way to tackle any river crossings or tunnel under man-made structures.

Whereas the traditional technology for pipeline river crossings has typically been Horizontal Directional Drilling, which has higher risk of frac-outs into the surrounding rivers or fields, the technology used by IPC, the biggest Direct Pipe® provider in the country, is based on a micro-tunneling machine (AVN) which uses a slurry circuit to pump excavated material out of the pipeline, decreasing frac out risk.

“IPC and Direct Pipe® were selected for the Credit River crossing because this technology allowed for a shorter and shallower crossing profile that wouldn’t have been possible using the HDD method, due to boulders and unfavorable geotechnical conditions,” says Jim Murphy, Engineering Consultant for UPI.

Arash Jaraiedi, Project Manager of Pipeline Projects with TransCanada Pipelines, recalls the first National Energy Board-sanctioned Direct Pipe® installation in Canada. “We wanted to make sure [the nearby landowners] felt very comfortable and confident about the technology. We brought forward IPC earlier than usual, and IPC really helped us during the design including preplanning and pre-construction planning for this particular project. As a result of all this collaboration, great conversations, and of course a very good relationship that was established during the lifecycle of the project, construction went very well and was successful.”

Bothar Group of Companies

With its presence firmly established in the pipeline industry, in October, 2018, IPC focused on strategically diversifying its portfolio by amalgamating with Bothar Boring, one of the largest tunneling and trenchless contractors in the world.

“We can now have the opportunity to operate on a much broader scale,” says Peter Hennig, CEO of IPC, “and will be able to expand from the oil and gas sector into others, such as municipal and civil works, with a focus on Canada’s infrastructure program.”

IPC is now able to provide Tunneling, Microtunneling, and Auger Boring services ranging from 300mm up to 4.000mm. While the first Auger Boring equipment has landed in Calgary and is already getting prepared for the next job, IPC is involved in tendering for major Microtunneling projects throughout the country. Additional resources are being mobilized to Calgary to support the team during this growth period.

“We have massive programs in Canada to spend billions on new infrastructure to support economic growth,” says Hennig. “There is a great rise in urbanization happening now, and with the growing population, Canadian cities will grow and need more underground utilities like sewer, water supply, power supply, etc. [With the amalgamation] we will now be able to participate in those programs with our variety of trenchless solutions.”

Acceleration is full-steam ahead. Currently IPC is preparing for six Direct Pipe installation projects for TransCanada, in addition to municipal projects in Calgary and Vancouver. Hennig says IPC is a preferred partner in the industry for its combination of technology and its record of maintaining exceptional client relations. “Our overall approach to a project and with the client is very transparent,” he says. “We are of a mindset of providing solutions for our clients before they even anticipate the challenge. We walk our clients with us throughout the process and have been told it is is one of our strengths.”

Hennig has a unique perspective on the industry; Canada is the 42nd country in which he has worked. He has seen different approaches to environmental stewardship. “The level of approval process with National Energy Board and with pipeline owners like TransCanada and Enbridge…what they try to achieve here in this country is outstanding to what I’ve seen in other parts of the world,” says Hennig. “We are here to serve those requirements, to ensure the owners are completely compliant with these rules and regulations and processes that are in place. The projects we work on have a lot of environmental and First Nations inspections, and our low-impact technology and processes don’t allow for major spills or footprints in the environment, which aligns with their requirements.”

IPC is set to make an impact this year in the trenchless industry, and Hennig says he anticipates higher revenues, increased jobs for Canadians, and more competitive bids between contractors as some of the benefits to the industry resulting from IPC’s expansion this year.